-

Reasonable Setting of Injection Mold Temperature Parameters

The rational setting of injection mold temperature parameters is central to balancing part quality, molding efficiency, and production stability. Its core logic lies in precisely regulating the temper

2026/02/02 Injection Mold

-

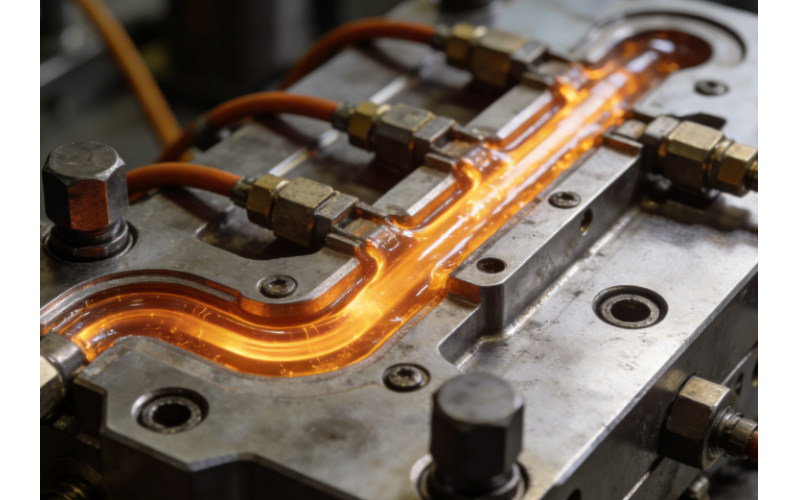

Troubleshooting Hot Runner Clogs in Injection Molds

The hot runner system is critical to stable production and part quality in injection molding. Clogging causes short shots, insufficient filling, burning, and leakage, and may damage heating components

2026/01/31 Injection Molds

-

Selection of Gate Types for Plastic Molds

The gate is the critical channel through which molten plastic enters the mold cavity from the runner system. Its type directly affects melt filling behavior, part appearance, internal stress, producti

2026/01/31 Plastic Molds

-

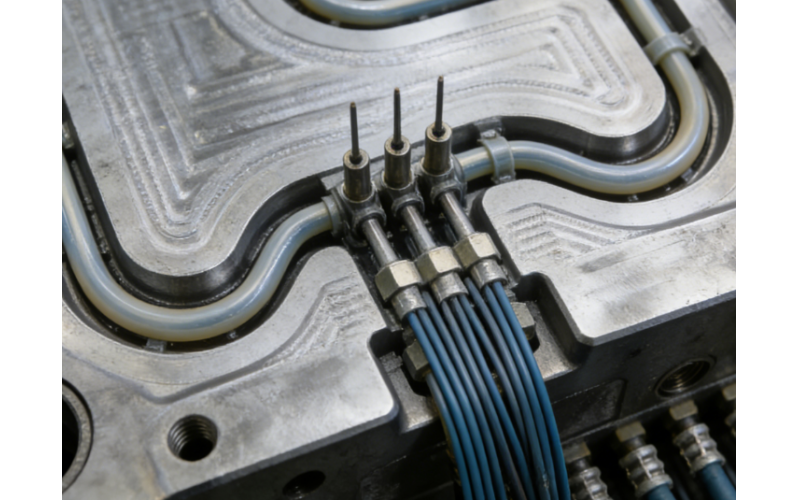

Design Principles of Cooling System for Plastic Molds

The cooling system of plastic molds is a core structure that determines injection molding efficiency, part dimensional accuracy and surface quality. It quickly and uniformly removes heat released duri

2026/01/31 Plastic Molds

-

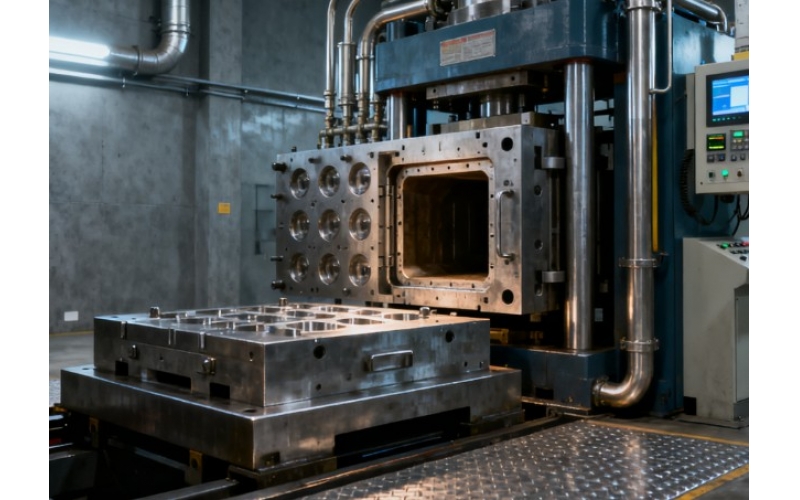

Injection Mold Vent Groove Design

Vent groove design is critical for injection molding quality and stability. It expels cavity air, volatile gases from melt decomposition, and residual gas in parting and insert gaps, avoiding defects

2026/01/31 Injection Mold

-

Material Selection for PE Molds

PE (polyethylene), a crystalline general-purpose plastic, features good melt flowability, low corrosiveness, and moderate shrinkage. Material selection for PE molds must align with its molding charact

2026/01/31 Plastic Molds

-

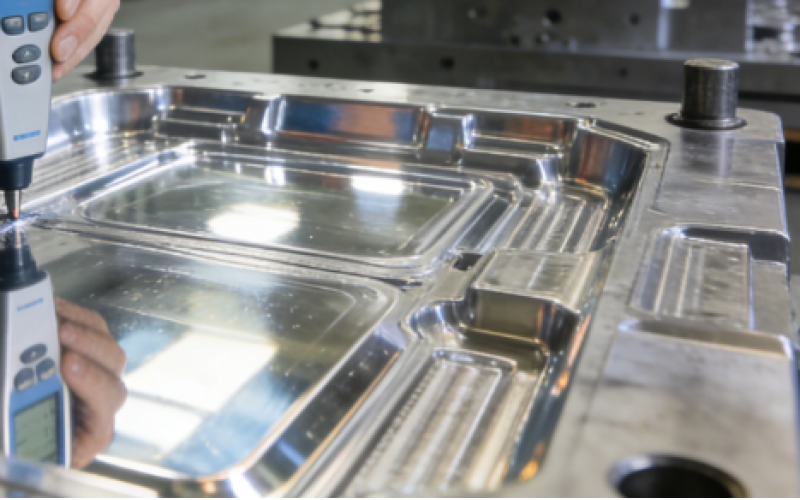

Control of Injection Mold Cavity Polishing Grade

The polishing grade of an injection mold cavity directly determines part surface finish, ejection performance, and mold lifespan. Proper polishing ensures uniform melt flow, reduces mold sticking, and

2026/01/30 Injection Mold

-

Design Points of Plastic Mold Runner

I. IntroductionThe runner system in plastic molds is the critical channel that delivers melt from the nozzle to the cavity. Its design directly impacts melt flow, filling balance, part quality, and ma

2026/01/30 Plastic Mold