Troubleshooting Hot Runner Clogs in Injection Molds

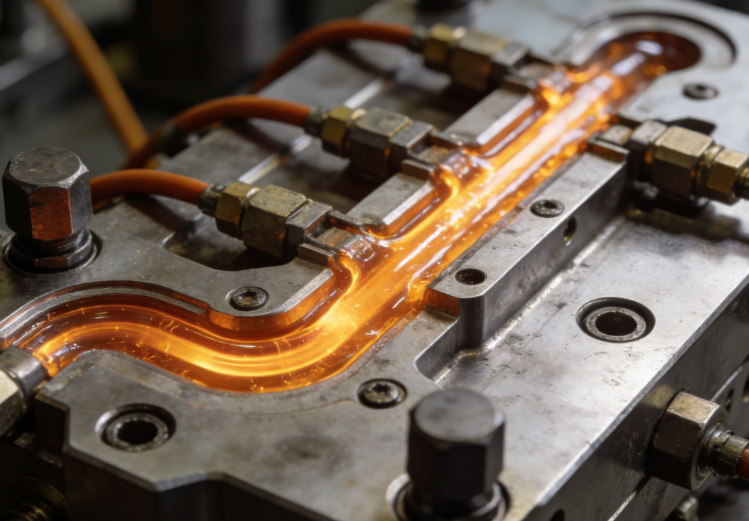

The hot runner system is critical to stable production and part quality in injection molding. Clogging causes short shots, insufficient filling, burning, and leakage, and may damage heating components and nozzles, leading to costly downtime. Effective resolution requires accurate root-cause analysis, stepwise troubleshooting, and long-term preventive measures.

I. Common Causes of Hot Runner Clogging

Material residue and carbonization: Thermally sensitive resins (PVC, POM, PET) or fiber/mineral-filled materials degrade and carbonize in dead zones, corners, and nozzle tips, forming hard deposits.

Foreign material intrusion: Metal chips, packaging fragments, dryer filter debris, or sealant residues enter the system and lodge at nozzle openings or narrow manifold channels.

Temperature control issues: Low setpoints cause premature solidification; faulty heaters or thermocouples create uneven temperatures; overheating accelerates material degradation, resulting in cold slugs or coke buildup.

Design and machining flaws: Dead spots, sharp corners, rough inner surfaces, or improper matching gaps between nozzles and manifolds trap melt and contaminants.

II. On-Site Emergency Measures

Thermal softening: Raise hot runner temperatures 10–20°C above normal and hold for 10–30 minutes to soften clogs. Use low-pressure, low-speed injection attempts to push out blockages (avoid with heat-sensitive materials).

External cleaning: With the mold partially open, clear nozzle?tip carbon or cold slugs using copper pins or dedicated tools; avoid steel tools to prevent surface damage.

Process and equipment checks: Inspect hoppers and dryers for contaminants, clean cold slugs at the nozzle-to-runner interface, and adjust injection parameters. For multi-cavity systems, isolate the clogged cavity if possible.

III. Full Disassembly, Cleaning and Repair

Safe disassembly: Power off heaters and cool the system below 80°C. Label components and disassemble in order: manifold, nozzles, heating elements, seals, to avoid misassembly or surface damage.

Component cleaning: Clean manifold channels with specialized pins, brass brushes, and high-temperature cleaners; soften heavy carbon before removal. Clear nozzle bores, polish light carbon layers, and rinse with alcohol. Remove resin residue from heaters and thermocouples.

Inspection and refurbishment: Check sealing and mating surfaces for scratches or deformation, and channels for wear or shrinkage. Replace failed heaters and thermocouples; repair minor surface damage by lapping; replace severely worn components.

Reassembly and testing: Reinstall in reverse order with new gaskets and seals. Heat gradually to operating temperature and hold for 30+ minutes. Perform air shots and trial runs to confirm no clogging, leakage, or temperature anomalies.

IV. Targeted Solutions for Different Clog Types

Resin residue and carbonization: Fully remove carbon layers; ensure thorough cleaning for heat-sensitive materials. For fiber-filled resins, inspect and polish channel surfaces, then blow dry with compressed air.

Metal and foreign material clogs: Use magnetic tools to extract metal chips. Identify and eliminate contamination sources, replace damaged filters, and standardize assembly practices.

Cold slug blockages: Repair temperature control systems, replace faulty components, calibrate setpoints, and conduct extended heat-soak tests to maintain consistent melt flow.

Coke deposits: Clean with dedicated hot runner cleaners or ultrasonic equipment after disassembly. Verify channel integrity to prevent re-clogging from loose coke particles.

V. Long-Term Prevention

Material and feeding control: Use properly dried resin; install double-layer hopper screens; clean hoppers and dryers regularly. Purge barrels and hoppers completely during material changes.

Process parameter control: Set temperatures according to resin properties; use staged heating for heat-sensitive materials to reduce residence time. Optimize injection speed and pressure; lower holding temperatures during production pauses.

Mold maintenance: Establish a periodic cleaning schedule; inspect heating and sensing elements, and replace worn seals. Clean the hot runner after production and protect the system from dust and chips during storage.

Design and manufacturing improvements: Use dead?space?free, radiused channel designs; select high?polish manifolds and nozzles; ensure proper matching clearances. Choose reputable hot runner systems for better precision and durability.

In summary, hot runner clog resolution should prioritize emergency response followed by thorough repair, with tailored methods for different failure modes. A comprehensive prevention strategy covering materials, processing, maintenance, and design minimizes downtime, protects system components, extends mold life, and supports consistent, efficient injection molding production.