Design Principles of Cooling System for Plastic Molds

The cooling system of plastic molds is a core structure that determines injection molding efficiency, part dimensional accuracy and surface quality. It quickly and uniformly removes heat released during plastic melt solidification, shortens the molding cycle, and avoids defects such as warpage, sink marks and excessive internal stress caused by uneven cooling. The cooling system design should follow scientific principles by combining mold structure, plastic properties, part geometry and production requirements, balancing cooling efficiency, structural reliability and production economy.

I. Cooling Uniformity Principle

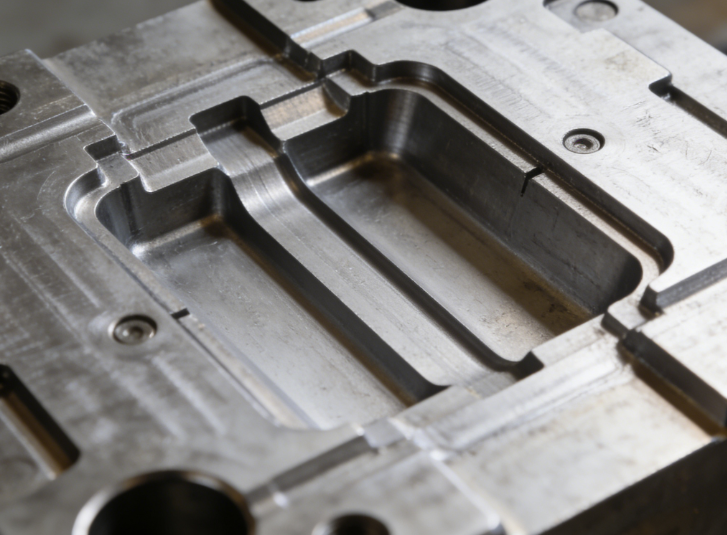

Cooling uniformity is the core principle, requiring consistent cooling rates across all part areas to avoid excessive local temperature differences. Cooling channels should be arranged evenly along the part contour; channels should be densified or spaced narrower in heat-concentrated areas such as thick sections, ribs and bosses, and properly widened in thin-wall areas. For multi-cavity molds, independent and identical cooling circuits for each cavity are necessary to prevent quality inconsistency caused by uneven cooling between cavities. The distance between channels and cavity surfaces should be stable to control temperature fluctuation within a reasonable range, fundamentally reducing part warpage and internal stress.

II. High-Efficiency Heat Transfer Principle

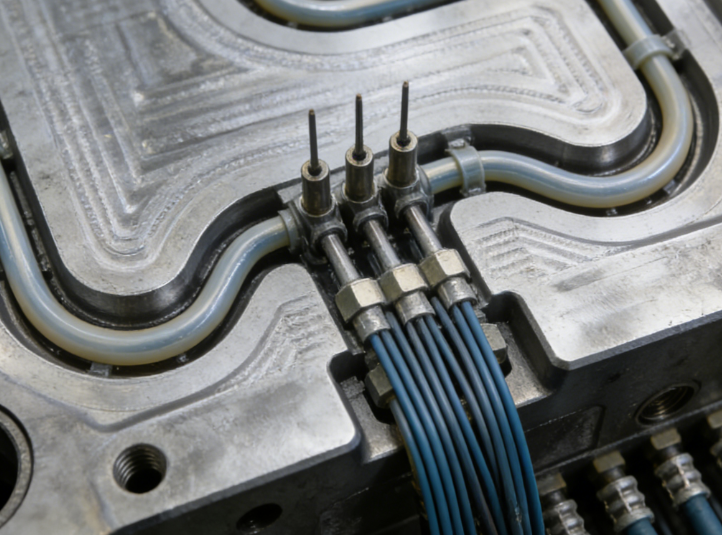

Maximize heat exchange efficiency within structural limits. Select appropriately sized cooling channels, with conventional diameters of 8–12mm (enlarged for large molds, 6–8mm for small precision molds) to ensure turbulent cooling water flow for better heat transfer. The distance between channels and cavity surfaces is generally 1.5–3 times the channel diameter, balancing heat transfer efficiency and mold strength. Adopt straight-through, circulating or stepped channel layouts to reduce flow resistance and avoid dead zones. High-conductivity materials like beryllium copper inserts can be used in heat-concentrated areas to enhance local cooling.

III. Structural Safety and Strength Assurance Principle

Cooling system design must not compromise mold structural strength and operational safety. Channels should avoid core stress areas of cavities and cores, and stay away from key structures such as guide pillars, guide bushes, ejector pins and insert seams to prevent cracking or interference. Pressure-resistant sealed joints and plugs should be used, with working pressure matching the injection machine’s cooling system to avoid water leakage. Channel inner walls must be smooth to prevent scale buildup, and rounded corners are adopted to reduce stress concentration and flow loss.

IV. Adaptation to Plastics and Molding Processes

The cooling system should match the thermal properties and processing requirements of plastics. Crystalline plastics (PP, PE, PA) release large heat during crystallization, requiring more efficient cooling circuits with higher flow rate and velocity. Amorphous plastics (ABS, PC, PS) can use conventional cooling designs; high-viscosity engineering plastics need controlled cooling temperature and flow rate to avoid poor melt filling. High-precision parts require constant-temperature cooling systems with temperature fluctuation within ±1℃ for dimensional stability, and transparent parts need optimized channel layout to avoid optical defects from uneven cooling.

V. Convenience in Maintenance and Assembly

The cooling system should be easy to clean, maintain and assemble. Channel layout should be concise with fewer complex bends and blind holes for scale and impurity removal. Inlet and outlet joints should be concentrated on one side of the mold for quick pipeline connection and mold change efficiency. Standardized plugs and seals are used for easy replacement, and cleaning ports are reserved at key channel positions to address clogging after long-term use, ensuring stable operation.

VI. Economy and Production Adaptation Principle

Design should balance manufacturing cost and production efficiency. Simplify channel structure and reduce complex processing to lower mold cost on the premise of meeting cooling needs. Adjust cooling configuration according to production volume: conventional circuits for small-to-medium batches, enhanced cooling with circulating and temperature control devices for high-volume production to maximize cycle shortening. Control cooling water consumption and energy consumption to avoid waste, achieving a balance between economy and cooling effect.

Summary

The design of plastic mold cooling systems takes cooling uniformity as the core, while considering high-efficiency heat transfer, structural safety, material adaptation, maintenance convenience and production economy. Scientific channel layout, parameter selection and structural design ensure stable part quality, shortened molding cycles and extended mold service life, supporting efficient and stable injection production.