Selection of Gate Types for Plastic Molds

The gate is the critical channel through which molten plastic enters the mold cavity from the runner system. Its type directly affects melt filling behavior, part appearance, internal stress, production efficiency, and mold complexity. Gate selection must integrate material properties, part geometry, appearance requirements, mold layout, and processing conditions to balance quality, manufacturability, and cost.

I. Key Considerations for Gate Selection

Material characteristics are fundamental: crystalline plastics (PP, PE, PA) require gates with sufficient cross-section to ensure proper packing and avoid uneven crystallization; high-viscosity engineering plastics (PC, PMMA) need low-resistance gates to ensure smooth filling; heat-sensitive plastics (PVC, POM) demand gates that minimize melt residence time to prevent degradation. Part structure and appearance requirements determine gate visibility and removal method: high-appearance parts favor sub-gates or pin-point gates for automatic degating; thick-wall parts need gates with strong packing capability; thin-wall and deep-cavity parts require gates that ensure balanced filling. Mold structure and production efficiency also constrain selection: two-plate molds suit side gates and fan gates; three-plate molds enable pin-point gates with automatic degating; multi-cavity molds require consistent gate parameters for balanced filling; high-volume automation favors self-degating gates to reduce labor. Finally, gate selection must avoid common defects such as jetting, weld lines, sink marks, and excessive residual stress, with special attention to optical and dimensional precision for high-value parts.

II. Common Gate Types and Applications

1. Direct Gate (Sprue Gate)

A large, direct channel from the sprue to the cavity with minimal flow resistance and excellent packing. Ideal for large, thick-wall, deep-cavity parts and high-viscosity materials in single-cavity molds. Simple to machine but leaves a large vestige requiring manual trimming, with high residual stress and potential sink marks.

2. Side Gate (Edge Gate)

The most widely used rectangular gate on the parting line for two-plate molds. Suitable for most general and engineering plastics, especially medium-small parts and multi-cavity layouts. Easy to design and machine, with adjustable size for flow control, but leaves a visible mark and may cause jetting without proper transition.

3. Pin-Point Gate

A small, round gate requiring a three-plate mold, which automatically breaks the gate during opening. Preferred for high-appearance and precision parts using materials with good flowability (ABS, PS, PP). Leaves almost no vestige but increases mold cost and may cause premature freezing, limiting packing for thick or high-viscosity parts.

4. Sub-Gate (Tunnel Gate)

A tapered, hidden gate below the parting line that shears automatically during ejection. Balances low-cost two-plate mold structure with automatic degating, suitable for appearance-critical parts and automated production. Concealed vestige but more difficult to machine and not recommended for brittle or high-viscosity materials.

5. Fan Gate

A widened, tapered variant of the side gate that distributes melt evenly. Reduces jetting and improves surface quality for flat, thin, or transparent parts (PMMA, PC). Enhances weld line quality but leaves a wider mark and consumes more parting-line space.

6. Flash Gate (Slit Gate)

A narrow, flat gate along the part edge that delivers melt in a uniform sheet. Excellent for large flat, thin, or transparent parts to minimize warpage and optical defects. Low stress and high dimensional stability but high flow resistance and difficult degating.

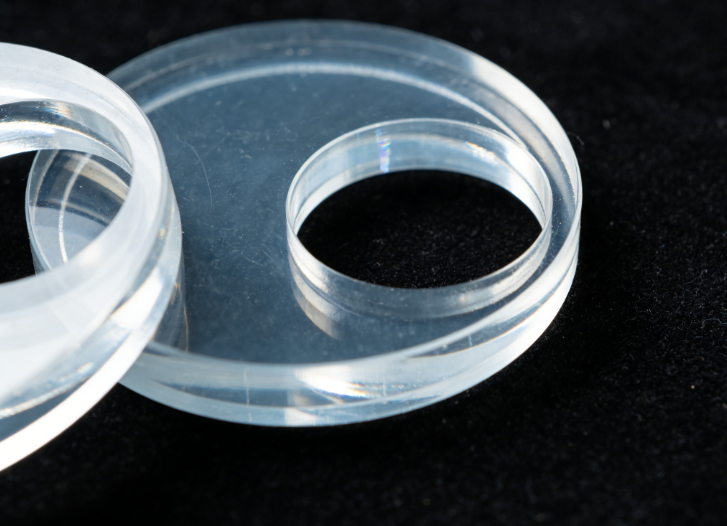

7. Ring Gate

A circumferential gate surrounding a core, providing uniform filling without weld lines. Designed for cylindrical or tubular parts (PE, PP, PA). Eliminates weld lines and ensures roundness but is complex to machine and limited to rotational parts.

8. Tab Gate

A small auxiliary cavity that receives melt before it enters the main cavity, reducing jetting and local stress. Used for high-viscosity and precision parts to improve surface quality. Eliminates gate-related defects but generates additional scrap and increases mold complexity.

III. Gate Selection Procedure

First, evaluate material flow, viscosity, crystallinity, and thermal stability to define allowable gate size and type. Second, analyze part geometry, wall thickness, appearance standards, and performance requirements to establish gate visibility and packing needs. Third, match with mold type (two-plate/three-plate), cavity count, and automation level to filter structurally and economically feasible gates. Fourth, use mold-filling simulation to verify filling, packing, and cooling, optimizing gate location and size. Finally, validate via mold trials, adjusting dimensions or type to resolve filling, appearance, or dimensional issues.

IV. Optimization for Special Applications

Precision parts use pin-point or sub-gates with controlled size and velocity, paired with temperature-controlled cooling. Transparent optical parts employ fan or flash gates to avoid blemishes and degradation. Deep-cavity and thick-wall parts rely on direct or ring gates for filling and packing, with hot-runner gates for high-volume production. Multi-cavity molds use balanced side or pin-point gates for consistency. Thin-wall parts (<1mm) use fan or flash gates to lower resistance and speed filling, while brittle materials avoid sub-gates to prevent cracking during degating.

Summary

Gate selection is a holistic decision based on material compatibility, part design, mold structure, and production requirements. By systematically evaluating constraints, simulating performance, and validating through trials, designers can select the optimal gate type to ensure smooth filling, high part quality, and cost-effective, stable production.