Injection Mold Vent Groove Design

Vent groove design is critical for injection molding quality and stability. It expels cavity air, volatile gases from melt decomposition, and residual gas in parting and insert gaps, avoiding defects like burning, bubbles, short shots, weak weld lines and silver streaks. Proper venting also reduces cavity pressure, lowers clamping force consumption and extends mold life. The design must match plastic properties, part structure, gate layout and mold parting structure, balancing exhaust efficiency and anti-flash requirements.

I. Core Design Principles

I.1 Targeted Layout: Set vents at gas accumulation zones, last-fill areas and weld line positions to avoid redundant design.I.2 Anti-Flash Priority: Control groove depth below the material’s flash limit to prevent overflow, while ensuring adequate exhaust speed.I.3 Strength Preservation: Avoid mold core stress areas to prevent weakening of parting surfaces, inserts and ejection mechanisms.

II. Key Design Parameters

II.1 Depth: PE/PP (low viscosity): 0.015–0.03 mm; ABS/PS (medium viscosity): 0.02–0.04 mm; PC/PMMA/PA66 (high viscosity): 0.01–0.02 mm. Glass-filled materials use lower depth limits to avoid wear-related flash.II.2 Width & Length: Main vents: 5–10 mm wide, 5–20 mm long; auxiliary vents: 3–5 mm wide, 3–10 mm long. The rear of main vents can be deepened to 0.5–1 mm for smoother exhaust.II.3 Structure: Rectangular cross-section with smooth walls, no blind grooves to prevent gas trapping.

III. Zone-Specific Vent Design

III.1 Parting Surfaces: Install main vents at last-fill positions; add auxiliary vents every 20–30 mm for large parts.III.2 Inserts & Cores: Add 0.01–0.02 mm micro-grooves at insert seams or use relief gaps, with bottom channels connecting to the outside.III.3 Ejection Components: Control fitting clearances below flash limits, add annular vents at pin hole bases and concentrate vents in dense ejection areas.III.4 Gates & Weld Lines: Set auxiliary vents opposite gates and at weld line zones to eliminate trapped air and improve weld strength.

IV. Optimization for Special Materials & Products

IV.1 Deep-Cavity Parts: Use vent pins or inserts with spiral micro-grooves to guide deep gas to parting surfaces.IV.2 Thin-Walled Parts (<1 mm): Increase vent density (spacing 10–15 mm) and use minimum depth to avoid short shots or burning.IV.3 High-Flow Materials (PP/PE): Limit depth ≤0.03 mm and adopt segmented short vents.IV.4 High-Viscosity Plastics (PC/PMMA): Use depth ≤0.015 mm and multiple auxiliary vents to avoid surface defects.

V. Operational & Maintenance Notes

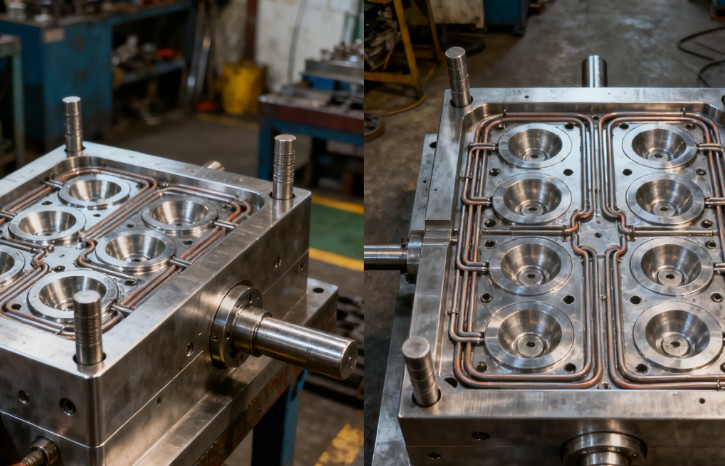

V.1 Avoid high-pressure zones like guide pin areas to maintain mold rigidity.V.2 Route vent outlets away from operators and ensure full connection to the exterior.V.3 Clean vents regularly, especially for volatile materials like PVC and POM, to prevent clogging.V.4 For multi-cavity molds, use independent, identical vents for each cavity to ensure consistent part quality.

VI. Summary

Effective vent groove design matches plastic characteristics and part geometry with reasonable dimensions and layout. Balancing exhaust efficiency, anti-flash performance, structural strength and maintainability ensures stable injection molding, consistent part quality and economical long-term production.