Material Selection for PE Molds

PE (polyethylene), a crystalline general-purpose plastic, features good melt flowability, low corrosiveness, and moderate shrinkage. Material selection for PE molds must align with its molding characteristics, product application requirements, production volume, and molding processes (mainly injection and blow molding). While standard PE products have low corrosion resistance demands for molds, modified PE increases wear risk, and food-grade or high-gloss products require materials with excellent polishability and non-migratory properties.

1. Core Principles of PE Mold Material Selection

The core logic is balancing mold service life, product quality, and production cost. Key principles include matching PE material properties (focusing on wear resistance for standard vs. modified PE with fillers like glass fiber), adapting to production volume (prioritizing cost and machinability for small-to-medium batches, durability for high-volume production), and meeting product specifications (controlling material purity for food-grade applications and enhancing polishability for high-gloss products).

2. Material Selection for Injection Molding PE Molds

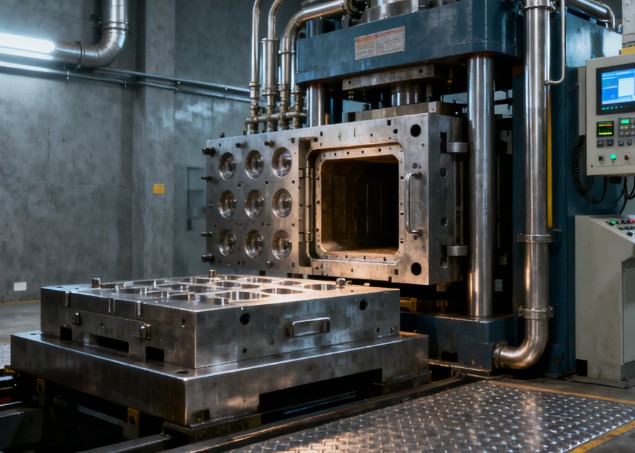

Injection molding is the primary process for PE products, with cavity and core materials selected based on PE type and production volume.

2.1 Standard PE Injection Molds: Pre-Hardened Plastic Mold Steels

For small-to-medium batch production of standard LDPE/HDPE products, pre-hardened steels such as P20 and 718H (28–35 HRC) are preferred. They require no post-heat treatment, offer good machinability, and achieve surface roughness of Ra ≤ 0.8 μm, suitable for daily necessities and packaging. NAK80 is ideal for transparent or food-grade PE products, providing mirror-finish polishability (Ra ≤ 0.05 μm) and no heat treatment distortion.

2.2 Modified PE Injection Molds: Wear-Resistant Mold Steels

Modified PE with glass fiber or mineral fillers demands high wear resistance. H13 and SKD61 hot-work die steels (48–52 HRC after quenching and tempering) resist abrasive wear. For ultra-high-volume or high glass fiber content (≥30%) products, powder metallurgy high-speed steels like ASP23 further extend service life.

3. Material Selection for Blow Molding PE Molds

Blow molding prioritizes cooling efficiency and wear resistance of critical components, differing significantly from injection molding.

3.1 Standard PE Blow Molds: Aluminum Alloys

6061 and 7075 aluminum alloys are mainstream for small-to-medium batch standard PE blow molds (bottles, drums). With 3–5 times the thermal conductivity of mold steels, they accelerate cooling and boost productivity, and are lightweight and easy to machine for complex cavities, though limited to non-filled PE.

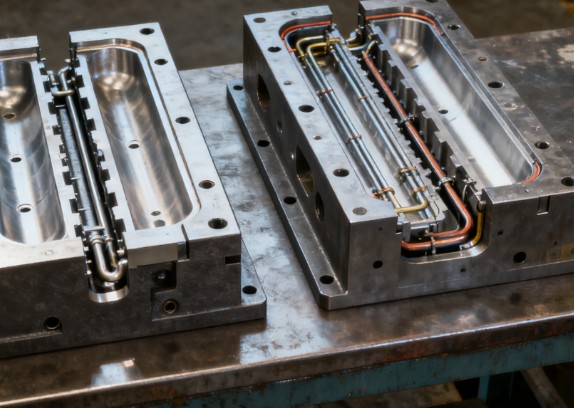

3.2 Modified PE Blow Molds: Mold Steel Bodies with Wear-Resistant Inserts

For high-volume modified PE production, P20 or 718H pre-hardened steels form the cavity body for strength and basic wear resistance. Critical wear parts (pinch-off, blow pins, cutters) use YG8 cemented carbide or SKH51 high-speed steel inserts to withstand shear and reciprocating wear, with replaceable inserts reducing maintenance costs.

4. Material Selection for General PE Mold Components

General components focus on wear resistance for guiding, ejection, and gating, with cost-effective choices. SUJ2 bearing steel (60–62 HRC) suits standard PE for ejector pins, guide pins, and bushings. Modified PE requires SKD61 for ejector pins and sprue bushings to resist abrasive wear. Stainless steel tubes suffice for cooling systems, as PE melt has low corrosiveness.

5. Summary

PE mold material selection is scenario-specific: pre-hardened steels (P20, 718H, NAK80) for standard PE and small-to-medium batches; hot-work or powder metallurgy steels (H13, SKD61, ASP23) for modified PE and high-volume production; aluminum alloys or mold steels for blow molding with wear-resistant inserts for critical parts. Adjusting for food-grade and high-gloss requirements balances service life, quality, and cost for stable, efficient PE production.