Design Points of Plastic Mold Runner

I. Introduction

The runner system in plastic molds is the critical channel that delivers melt from the nozzle to the cavity. Its design directly impacts melt flow, filling balance, part quality, and material waste. A well-designed runner system ensures uniform filling, minimal pressure loss, and efficient production. This article outlines key design principles and best practices for both cold and hot runners.

II. Core Basic Principles

Runner design must adhere to four core principles:

Balanced Filling: Ensure melt reaches all cavities/gates simultaneously to avoid dimensional variation and defects.

Low-Resistance Flow: Use rounded corners (R≥1.5mm) and polished inner walls (Ra≤0.8μm) to minimize shear and pressure drop.

Temperature Stability: Optimize layout to reduce heat loss, ensuring consistent melt temperature at the cavity.

Economic Efficiency: Minimize runner length and volume to reduce scrap and cycle time, while simplifying mold maintenance.

III. Cold Runner Design

Main Runner: Tapered (2°-4°) for easy ejection, length ≤60mm, with a 0.05-0.1mm gap at the nozzle interface to prevent leakage and cold material ingress.

Branch Runner: Use circular, trapezoidal, or U-shaped cross-sections (circular for best flow). Diameter ranges from 4-10mm (adjust by material), with symmetric, equal-length layouts for multi-cavity molds.

Cold Slug Well: Position at the end of the main runner and branch runners, with a volume 1-1.5x the runner cross-section. Z-type or inverted cone designs effectively trap cold material and aid ejection.

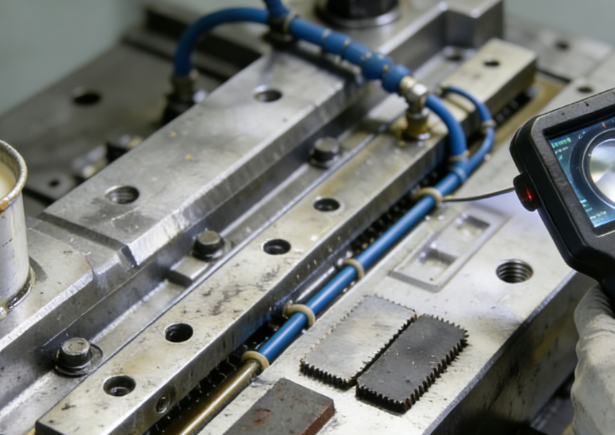

IV. Hot Runner Design

Heating & Temperature Control: Use independent zone control (temperature deviation ≤±2℃) with insulated heating elements to maintain melt temperature. Insulate the hot runner plate from the mold base to reduce heat loss.

Sealing: High-temperature seals (0.02-0.05mm gap) prevent melt leakage at nozzles and joints.

Gate Design: Needle-point or valve gates are preferred. Valve gates prevent drooling for low-viscosity materials, while anti-cold material structures at nozzles avoid cold slug entry into cavities.

V. Coordination with Other Systems

Gate Interface: Ensure smooth transitions between runners and gates, with runner cross-sections slightly larger than gates to minimize shear.

Cooling System: For cold runners, place cooling channels 8-15mm from runners to speed up solidification; for hot runners, isolate from cooling channels to maintain temperature stability.

Exhaust System: Add exhaust grooves (0.01-0.05mm deep) at runner ends and corners to vent trapped gas, preventing gas marks and burn marks.

VI. Conclusion

A well-engineered runner system is fundamental to high-quality injection molding. By following these design principles and best practices for both cold and hot runners, manufacturers can achieve balanced filling, reduce waste, and enhance production efficiency.