PE Injection Mold Material

I. Introduction

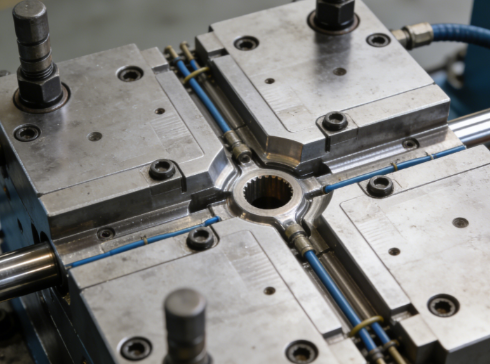

Polyethylene (PE) is one of the most widely used general-purpose thermoplastics, valued for its excellent melt fluidity, low molding temperature, and weak tendency to stick to molds. The selection of mold materials for PE injection molding does not require ultra-high temperature resistance, but must be precisely matched to production volume, surface finish requirements, and working conditions, while balancing processability, polishability, and wear resistance. This article outlines a systematic approach to material selection and post-treatment for PE injection molds, ensuring that each component of the mold delivers optimal performance throughout its lifecycle.

II. Core Selection Principles

The key to mold material selection for PE is to align the material’s properties with the application scenario. For standard PE applications, the focus is on ensuring uniform melt filling and consistent surface quality; for glass fiber-reinforced PE, the priority shifts to high wear resistance to withstand the abrasive action of glass fibers, which can rapidly degrade mold surfaces over time. The goal is to use the most cost-effective material that meets performance needs without over-engineering, as over-specifying materials can lead to unnecessary costs and longer lead times.

III. Material Recommendations by Scenarios

Basic General Applications (Small-batch civil parts)P20/718H pre-hardened steel is ideal for small-batch production of everyday PE items such as containers, pipes, and simple components. Delivered in a pre-hardened state (28-35HRC), it offers excellent machinability, allowing for efficient milling, drilling, and polishing to a surface finish of Ra0.4-0.8μm. 718H, with its more uniform chemical composition and refined microstructure, is better suited for larger mold cavities, providing improved dimensional stability and resistance to deformation during production runs.

Medium to High Production Volume (Conventional precision parts)For medium to high volume production of precision PE components like caps, closures, and automotive interior parts, NAK80/S136H are preferred. NAK80 achieves a semi-mirror finish (Ra0.05μm) with a pre-hardened hardness of 38-42HRC, ensuring long-term dimensional stability and resistance to wear even after millions of cycles. S136H, a corrosion-resistant stainless steel, provides superior protection against moisture and chemical exposure, making it suitable for humid production environments and basic food-grade applications where hygiene is a concern.

Precision High-gloss Applications (Food/medical parts)For food-contact and medical-grade PE components, such as packaging containers and diagnostic devices, quenched S136/HPM38 is the top choice. After vacuum quenching, it reaches a hardness of 50-55HRC and can be polished to a mirror finish (Ra0.025μm). Its high purity, achieved through vacuum degassing, ensures no harmful impurities leach into the PE melt, complying with strict FDA and EU food safety regulations. HPM38, an upgraded version of S136, offers even better polishability and wear resistance, making it ideal for ultra-high-precision applications.

Special Working Conditions (Glass fiber-reinforced PE parts)For PE components reinforced with glass fibers, such as structural automotive parts and industrial housings, SKD61/H13 hot work die steel is recommended. With a hardness of 52-58HRC after quenching, it offers exceptional erosion resistance to withstand the abrasive impact of glass fibers. A mandatory gas nitriding or TD treatment (0.015-0.03mm thickness) further enhances surface hardness to over 65HRC, significantly extending mold life and reducing maintenance costs.

IV. Targeted Post-Treatment Requirements

General-purpose molds (P20/718H): A combination of polishing and low-temperature nitriding (480-520℃) increases surface hardness to 45HRC, improving wear resistance and reducing the risk of surface degradation over time.

High-volume molds (NAK80): Mirror polishing followed by stress relief annealing (550-600℃) eliminates residual machining stresses, preventing mold deformation during long production runs and ensuring consistent part quality.

Precision high-gloss molds (S136/HPM38): Vacuum polishing and vacuum quenching ensure uniform hardness and a defect-free mirror finish. For food-grade applications, an additional ultrasonic cleaning step removes all polishing residues, ensuring compliance with hygiene standards.

Glass fiber-reinforced PE molds (SKD61/H13): Gas nitriding or TD treatment forms a dense, wear-resistant surface layer that protects the mold from fiber erosion, maintaining surface integrity and reducing the need for frequent re-polishing.

V. Conclusion

By following these guidelines, manufacturers can select the optimal mold material for PE injection molding, ensuring high-quality parts, extended mold life, and cost efficiency. The right combination of material selection and post-treatment will directly translate to better product consistency, reduced downtime, and improved production stability, ultimately driving greater profitability in PE component manufacturing.