Key Notes for PP Plastic Injection Molding Production

PP plastic is a general-purpose thermoplastic crystalline material with excellent fluidity and a wide plasticization temperature range, but it also features high shrinkage and brittleness at low temperatures. For injection molding production, operations must be standardized across six core links with 20 key parameters controlled to ensure product quality and avoid common defects such as cold slug, sink mark and deformation. The detailed points are as follows:

1. Raw Material Pretreatment: Source Control to Reduce Molding Risks

Drying treatment: Only required if raw materials get damp or regrind absorbs moisture. Dry in hot air at 60-80℃ for 1-2 hours, control moisture content below 0.05%, and cool to room temperature before feeding to prevent thermal degradation.

Regrind usage: Crush and screen regrind to remove impurities first, with addition ratio ≤20% and single batch usage no more than 3 times to avoid molecular chain breakage and reduced toughness/strength of plastic parts.

Additive mixing: Add color masterbatch at 0.5%-2% and talcum powder/fillers at ≤30%. Excessive ratio impairs melt fluidity. Mix all additives thoroughly with virgin material to prevent local color difference and uneven fluidity.

2. Process Parameter Setting: Precise Adaptation for Efficiency and Molding Effect

Plasticization temperature: Control overall melt temperature at 180-240℃. Increase to 220-240℃ for thin-walled parts to enhance fluidity; keep at 180-210℃ for thick-walled parts to avoid material degradation and yellowing.

Mold temperature: 40-60℃ for thick-walled parts (slow cooling to reduce shrinkage cavity/sink mark); 20-30℃ for thin-walled parts (shorten cooling cycle for efficiency); 20-40℃ for general parts to meet basic requirements.

Injection pressure: 40-80MPa for general parts; 80-120MPa for thin-walled/complex parts (≤70% of rated equipment pressure) to prevent flash and excessive internal stress.

Injection speed: 50-150mm/s (medium-low speed) for simple parts to ensure uniform filling; 150-300mm/s (high speed) for thin-walled/complex parts, with well-matched mold venting to avoid weld lines caused by air trapping.

Packing parameters: Set packing pressure at 50%-70% of injection pressure. Pack for 2-5s for parts with 1-3mm wall thickness and 5-10s for 3-5mm to prevent deformation and gate stress cracking from improper packing.

Cooling requirements: Cooling time accounts for 60%-80% of the molding cycle to ensure full melt crystallization; control mold water channel temperature difference ≤±5℃ to prevent deformation from uneven cooling.

Back pressure & screw speed: Control back pressure at 0.5-3MPa and screw speed at 30-80r/min. Cooperate to improve plasticization uniformity, reduce air bubbles and avoid excessive shear degradation of materials.

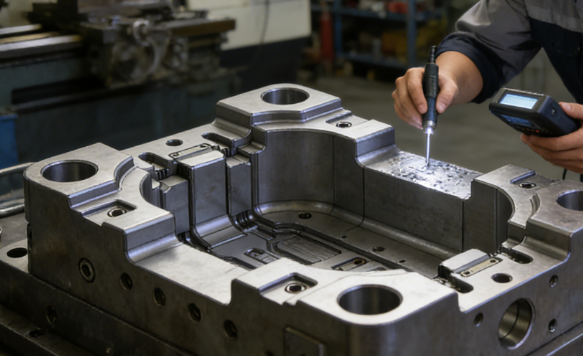

3. Mold Adaptation: Optimize Structure for Material Characteristics

Runner design: Prioritize circular cross-section to reduce flow resistance (main runner 4-6mm in diameter, sub-runner 3-5mm). Select gate type based on parts: fan/pin gate for thin-walled parts, thickened gate for thick-walled parts, and set gate away from stress-bearing areas.

Venting system: Set vent grooves (0.01-0.03mm in depth, 8-15mm in width) at cavity ends and weld lines to ensure timely air discharge and avoid air bubbles and short shot of plastic parts.

Shrinkage allowance: Reserve precise allowance according to PP's directional shrinkage (2.5%-3% in flow direction, 1.5%-2% in vertical direction) to ensure dimensional accuracy.

Demolding & surface treatment: Design uniform stress-bearing demolding mechanism, increase ejector pin quantity and contact area to prevent deformation from sticking. Polish cavity and runner to Ra≤0.8μm, with no sharp corners or steps to reduce melt friction and avoid degradation from stagnation.

4. Equipment Operation: Standard Debugging & Maintenance for Stable Production

Equipment selection: Choose based on part weight, control injection volume at 30%-80% of rated equipment volume to avoid uneven plasticization or melt degradation from long-term stagnation.

Screw configuration: Adopt general-purpose screw with length-diameter ratio 20:1-25:1. Inspect wear regularly and repair/replace in time for scratches or excessive gaps to prevent poor plasticization.

Nozzle & temperature control: Prioritize open nozzle (2-4mm in aperture) to avoid cold slug accumulation; control barrel temperature deviation ≤±5℃ for each section and calibrate temperature gauge regularly for precision.

Clamping control: Set clamping force at 40-60MPa/cm2 to balance mold tightness and anti-deformation. Inspect guide pillar/bushing fitting accuracy regularly and add lubricant in time for smooth clamping and opening.

5. Production Process Control: Real-time Inspection to Avoid Batch Defects

Raw material & equipment inspection: Check raw material dryness and mixing uniformity regularly to reject unqualified materials; verify barrel temperature, mold temperature and injection parameters timely, clean nozzle cold slug and ensure unobstructed mold cooling water channel.

Product sampling inspection: Implement strict first article inspection (full check of dimension, appearance and mechanical properties) and start mass production only after qualification; sample inspect every 30 minutes during mass production. Adjust mold temperature and packing pressure first for defects, then fine-tune injection pressure and speed slightly.

Environmental control: Keep production environment at 15-30℃ and humidity ≤70% to avoid internal stress cracking from rapid cooling after demolding; maintain clean site to prevent impurities from mixing into raw materials and affecting product quality.

6. Finished Product Post-treatment & Protection: Scientific Curing for Final Quality

Annealing treatment: Anneal thick-walled, precision and stress-bearing parts at 60-80℃ for 1-2 hours and cool slowly to room temperature to eliminate molding internal stress and reduce warpage and cracking risks.

Dimensional stabilization: Place general parts at room temperature for 24 hours to achieve full dimensional stabilization before packaging, avoiding condensation and deformation from immediate packaging.

Storage protection: Stack finished products in layers to prevent deformation from heavy pressure; store in dry, ventilated environment away from direct sunlight to avoid aging and embrittlement; prevent surface scratches from contact with sharp hard objects.