-

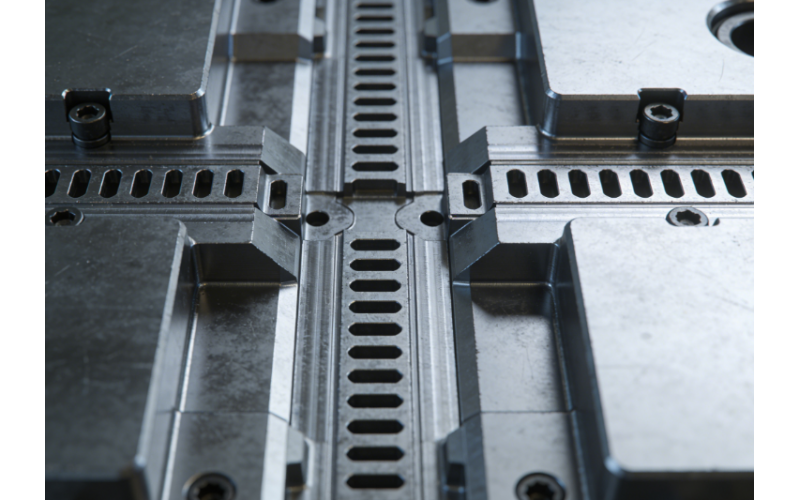

How to Unclog Cooling Channels in Plastic Injection Molds

The cooling system is one of the most critical parts of an injection mold. It directly affects cycle time, part dimensional stability, and surface quality. When cooling channels become blocked, heat t

2026/01/08 Injection Molds

-

Compliance Requirements for Food-Contact Plastics in Injection Molding

Material compliance is the fundamental prerequisite for the injection molding of food-contact plastics, directly impacting the safety of food products and consumer health. With the increasing stringen

2026/01/08 Injection Molding

-

Back Pressure in Injection Molding: Typical Ranges & Guidelines

Back pressure is a critical process parameter in injection molding, referring to the resistance applied to the screw during its backward rotation (plasticizing stage). Proper back pressure helps impro

2026/01/08 Injection Molding

-

How to Select Mold Steel for ABS Injection Molding

ABS is widely used in home appliances, automotive interiors, and electronics due to its good toughness, rigidity, and processability. Mold steel selection directly affects mold life, part surface qual

2026/01/08 Injection Molds

-

The Custom Plastic Mold Manufacturing Process

Custom plastic mold manufacturing is a complex engineering process that demands precision and strict quality control at every stage. From initial concept to final delivery, each step is critical to en

2026/01/08 Injection Molds

-

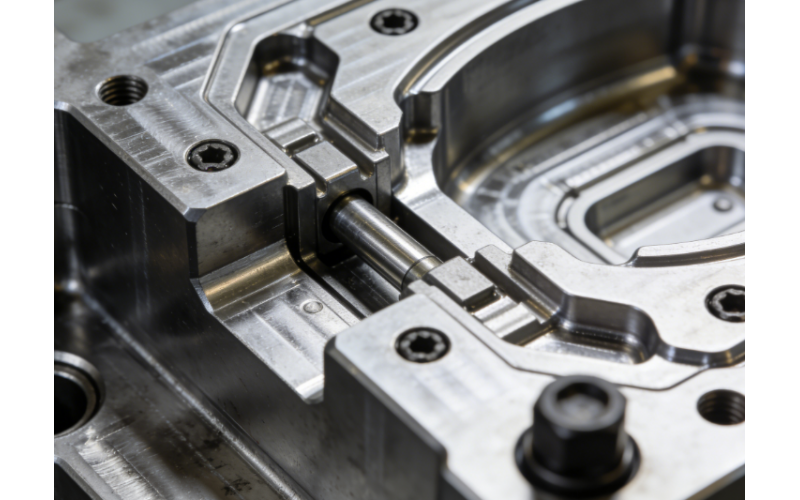

Eight Core Components of Injection Molds

Injection molds are key equipment for injection molding, whose structural design directly determines product precision, production efficiency and mold lifespan. The eight universally recognized core c

2026/01/07 Injection Molds

-

ABS Mold Vent Depth

In ABS (Acrylonitrile-Butadiene-Styrene) injection molding, mold vent system design directly impacts product quality, molding efficiency and mold lifespan. As a core parameter, vent depth must precise

2026/01/07 Injection Molds

-

Common Plastics Shrinkage Rate Overview

Plastic shrinkage rate is a core process parameter for injection mold design and product manufacturing, directly determining the accurate calculation of mold cavity dimensions, product dimensional sta

2026/01/07 Plastic Molds