Mold Steel Selection for PE Products

PE (polyethylene), a widely used general-purpose plastic, features non-abrasiveness, low melt viscosity, crystallinity, low molding temperature and non-corrosiveness. The core requirements for mold steel lie in release property, dimensional stability and polishability. For glass fiber modified PE, the mold steel only needs moderate wear resistance, and high-alloy, high-hardness mold steel is unnecessary. The selection of mold steel for PE products is mainly based on product appearance requirements, production batch and glass fiber modification, balancing mold manufacturing cost and service stability. The following are industry-recognized solutions covering all PE injection molding scenarios.

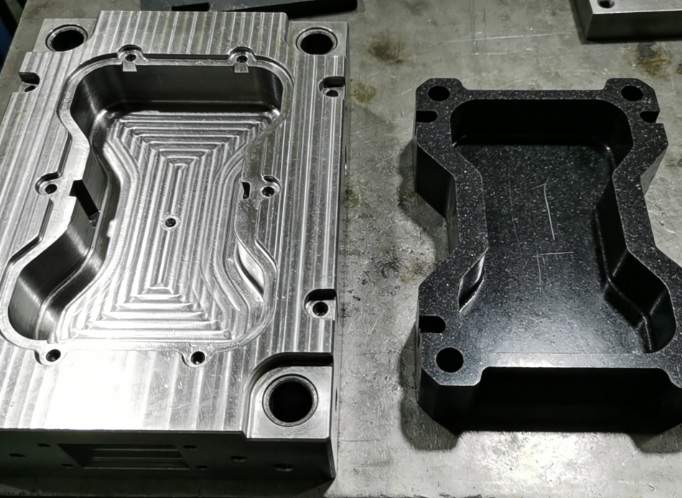

1. General Mass-Produced Ordinary PE Products

For ordinary PE products without high-gloss requirements (e.g., regular pipes, plastic barrels, turnover boxes) with a production batch of ≤500,000 shots, cost-effective pre-hardened plastic mold steels are preferred, such as P20 (3Cr2Mo) and 718H (3Cr2NiMo). P20 has a pre-hardened hardness of 28-32HRC, good machinability and can be polished to Ra≤0.8μm, suitable for simple-structure molds. 718H, an improved version of P20 with a hardness of 30-35HRC, offers better dimensional stability and polishability (Ra≤0.4μm), ideal for molds with moderate complexity and the mainstream choice for general PE mass production.

2. High-Gloss Precision PE Products

For high-gloss, mirror-finish PE products (e.g., food packaging containers, precision PE parts) with a production batch of 500,000-1,000,000 shots, mold steels with excellent mirror polishability, release property and dimensional stability are recommended, including NAK80 and S136 (4Cr13MoV). NAK80 is a pre-hardened mirror mold steel with a hardness of 38-42HRC, machinable without heat treatment and polishable to a super mirror finish of Ra≤0.05μm. S136, a stainless steel mirror mold steel with a hardened hardness of 48-52HRC, has good corrosion resistance, ensuring long-term surface smoothness and no sticking, making it a high-end choice for food-grade and precision high-gloss PE products.

3. Thin-Walled High-Speed Mass-Produced PE Products

For thin-walled PE products (e.g., thin-walled lunch boxes, disposable containers) with high production efficiency and a batch of ≥800,000 shots, mold steels with higher hardness, moderate wear resistance and excellent dimensional stability are preferred, such as P20HH and 738H. P20HH (32-36HRC) is a high-hardness version of P20 with better wear resistance, suitable for simple thin-walled mold structures. 738H (34-38HRC) features balanced performance, superior to P20HH in wear resistance and polishability (Ra≤0.4μm), ideal for high-speed mass production of thin-walled PE products with moderate mold complexity.

4. Glass Fiber Modified PE Products

Glass fiber modified PE (general fiber content ≤20%) has mild abrasiveness; for PE with 20%-30% fiber content, the abrasiveness slightly increases. S136H and H13 (4Cr5MoSiV1) are recommended. S136H, a pre-hardened improved version of S136 (30-35HRC), has good machinability, polishability and mild wear resistance, suitable for low-glass-fiber PE products with appearance requirements. H13, a hot work mold steel with a hardened hardness of 48-52HRC, features high hardness, excellent wear resistance and toughness, able to withstand the abrasion of medium and high glass fiber modified PE, suitable for products without high-gloss requirements.

Key Selection Points

Unmodified PE is non-abrasive and non-corrosive, so high-alloy wear-resistant steel is unnecessary to avoid extra cost.

As a crystalline plastic, PE has a large molding shrinkage, so the mold steel must have good dimensional stability to prevent cavity deformation.

Mold steel for high-gloss PE products requires a pure microstructure without inclusions to avoid pitting after polishing.

Select mold steel according to glass fiber content: mild wear resistance steel for ≤20% fiber content, and higher hardness steel for >20% fiber content.

Mold steel for food-grade PE products must meet food safety standards, with finely polished cavity surfaces to avoid material residue.

In summary, the core of mold steel selection for PE products is graded matching based on actual demands: P20/718H for general mass production, NAK80/S136 for high-gloss precision products, P20HH/738H for thin-walled high-speed mass production, and S136H/H13 for glass fiber modified products. Flexible adjustment can be made according to mold structure and production equipment to balance molding quality, mold life and manufacturing cost.