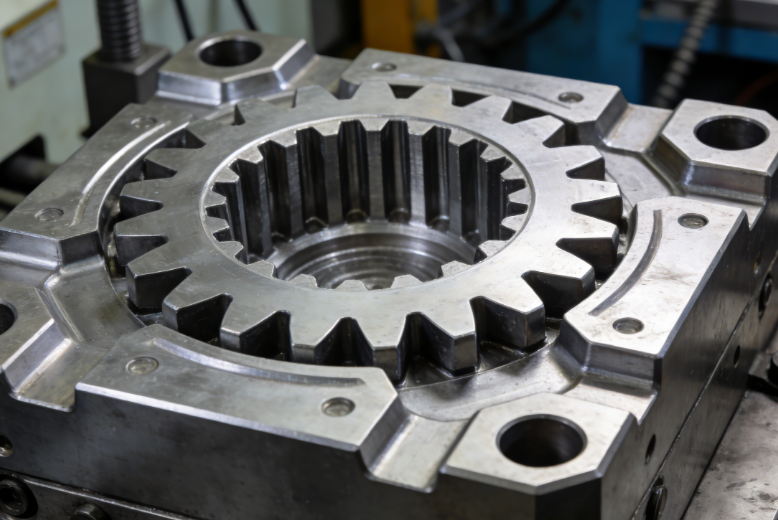

PE Material Spray-painted Shell Injection Mold Steel Selection Guide

PE (polyethylene) is widely used in the production of spray-painted shell appearance parts for the automotive, home appliance and consumer electronics industries due to its advantages of light weight, strong corrosion resistance and controllable cost. Such products not only require regular shape after injection molding, but also meet the core requirement of high surface flatness and low defects for the substrate in the spray painting process. The selection of mold steel directly determines the molding quality, production efficiency and comprehensive cost of PE spray-painted shells. Given that PE features low viscosity and a low molding temperature (160-220℃), the mold steel does not need ultra-high thermal strength, and the core of selection focuses on the balance of polishability, corrosion resistance, machinability and mass production adaptability. The following elaborates on the selection schemes and core points in combination with different production requirements.

1. Mainstream General-purpose Mold Steel: Cost-effective Choice

For the mass production of PE spray-painted shells with medium appearance requirements, S136 and H13 (SKD61) are the mainstream general-purpose mold steels in the industry, balancing performance and cost. S136 is a mirror stainless steel, with a surface roughness of up to Ra0.025μm after fine polishing, which can provide a flat substrate for PE injection molded parts and fundamentally avoid defects such as sagging and shrinkage cavities after spray painting. Its corrosion resistance can resist trace corrosive gases generated during PE molding, reduce cavity fouling and extend the cleaning cycle, making it suitable for products with high cleanliness requirements such as home appliance shells and electronic device sheaths.

H13 (SKD61) is characterized by excellent thermal strength and wear resistance, suitable for large-batch continuous production. This steel grade has outstanding thermal fatigue resistance, which can withstand the periodic temperature changes during PE melt filling and avoid thermal cracks in the cavity. After nitriding treatment, its surface hardness can reach more than HV800, reducing melt erosion and wear. Meanwhile, it has excellent machinability and can accurately form complex cavities with curved surfaces and grooves, making it suitable for mass-produced products such as automotive interior parts and industrial equipment shells, with more cost advantages than S136.

2. High-end Precision Mold Steel: Guarantee for High Appearance and Ultra-mass Production

For PE spray-painted shells with Class A high appearance requirements, ultra-mass production or complex structures, high-end precision mold steels such as NAK80 and P20+Ni are required. NAK80 is a pre-hardened mold steel with an ex-factory hardness of HRC37-43, which can be processed without heat treatment, greatly shortening the mold manufacturing cycle. Its mirror polishability is close to that of S136, and the molded surface is free of sand holes and pinholes, reducing the pre-treatment processes of spray painting. It is suitable for high-end products such as consumer electronics shells and automotive instrument panels, and can maintain stable molding quality in ultra-mass production scenarios.

P20+Ni (e.g. P20Ni) has a pre-hardened hardness of HRC28-32, balanced comprehensive mechanical properties, and excellent polishability and weldability. For large and complex PE spray-painted shell molds, its toughness and anti-deformation capacity can resist the uneven stress of the cavity and ensure dimensional accuracy. The surface can remain flat after post-maintenance welding and repair without affecting the spray painting effect, making it an optimal steel grade for products such as large home appliance shells and automotive door panels.

3. Economical Mold Steel: Cost Choice for Small-batch Production

For simple PE spray-painted shells with small-batch production and low appearance requirements, economical mold steels such as 45# steel and 50# steel can be selected. After quenching and tempering treatment (HRC22-28), they can meet the basic molding requirements, with the advantages of low procurement cost and short processing cycle, suitable for R&D sample production or small-batch production of low-value-added products.

It should be noted that such steels have poor inherent polishability, so the cavity surface needs to be chrome-plated (coating thickness 0.02-0.05mm) to improve finish and wear resistance, temporarily meeting the basic requirements of spray painting. However, the chrome coating is prone to peeling off after long-term use and is difficult to repair, so it is only suitable for low-cost, short-cycle transitional production, not for large-batch continuous operation.

4. Core Principles for PE Material Mold Steel Selection

The selection shall follow three core principles to balance quality, efficiency and cost. First, match material characteristics, focus on polishability and basic wear resistance to ensure the cavity surface forms plastic parts with low defects and avoid spray painting defects. Second, adapt to mass production scale and appearance requirements: select economical steel for small-batch and low-requirement products, general-purpose steel for medium and large-batch conventional products, and precision steel for high-end products. Third, consider the mold structure: select steel with excellent machinability and weldability for complex cavities, and appropriately lower the requirements for simple structures to control costs.

In summary, the selection of mold steel for PE material spray-painted shells must be based on product appearance standards, mass production scale and structural characteristics to scientifically match steel grades. Reasonable selection can not only ensure molding and spray painting quality, but also optimize the whole life cycle cost of the mold, improve production efficiency, provide core equipment support for the downstream industry, and help enterprises enhance product quality and market competitiveness.