Key Considerations for ABS Plastic Injection Molding

ABS plastic, a terpolymer of acrylonitrile, butadiene and styrene, boasts excellent rigidity, toughness and process fluidity, and is one of the most widely used general engineering plastics in injection molding for home appliances, automotive, electronics and daily necessities. Its molding process is relatively simple, yet the water-absorbent butadiene component and inconsistent thermal stability of different components can easily cause defects like silver streaks, air bubbles, short shots, warpage and obvious weld lines with improper parameter control. To ensure the dimensional accuracy, surface quality and mechanical properties of molded parts, standardized control is essential throughout the process from raw material pretreatment, process parameter regulation, mold matching to post-processing. The following are industry-recognized core considerations with key process parameters, balancing practicality and professionalism.

1. Raw Material Pretreatment: Strict Drying to Avoid Water Absorption Defects

ABS resin has polar groups and strong hygroscopicity; granules absorb moisture easily during storage and transportation. Undried raw materials will cause vaporization in the high-temperature barrel, leading to silver streaks, air bubbles on the surface and pinholes inside, damaging appearance and performance.General drying standard: Dry ABS granules in a hot air dryer at 80-90℃ for 2-4h, with material layer thickness ≤5cm for uniform drying. For high-gloss and high-transparency parts, extend drying time to 4-6h at a constant 85℃ to avoid slight material degradation.Post-drying rules: Use dried materials immediately; re-dry for 1-2h if exposed to air for over 1h to prevent molecular chain breakage from repeated high temperature.Regrind control: The addition ratio of regrind shall be within 20%, and regrind must be crushed and dried to avoid affecting melt fluidity and part color.

2. Injection Temperature: Sectional Control for Fluidity and Thermal Stability

ABS has a melting temperature of about 170℃ and a decomposition temperature above 250℃, with a wide molding temperature window of 180-240℃ for the barrel. Sectional temperature control is required, increasing temperature gradually from the hopper to the nozzle to avoid local melt degradation or insufficient fluidity.Specific sectional temperature: Front barrel: 180-200℃, middle barrel: 200-220℃, rear barrel: 220-240℃, nozzle: 210-230℃. The nozzle temperature should be slightly lower than the rear barrel to prevent melt drooling.Structural adaptation: Raise the overall temperature by 5-10℃ for thin-walled and complex parts to improve fluidity; lower the rear barrel temperature to 210-230℃ for thick-walled parts to avoid internal shrinkage cavities.Barrel insulation: Melt residence time in the barrel ≤30min. Reduce temperature to below 150℃ for insulation during production interruption, and reheat gradually when resuming production to prevent material degradation.

3. Injection Pressure & Speed: Match Part Structure to Reduce Defects

ABS melt has moderate fluidity; the matching of injection pressure and speed directly affects mold filling. Insufficient pressure causes short shots, while excessive pressure leads to flash and internal stress, resulting in warpage and cracking. Overhigh speed causes air entrainment and obvious weld lines, while overlow speed leads to cold slug marks due to premature melt cooling.General parameters: Injection pressure: 60-100MPa, with medium to medium-high speed adjusted in 3-4 stages. Use low speed (20%-30% of rated speed) at initial filling to prevent cold slugs; medium-high speed (50%-70%) in the middle to reduce weld lines; low speed (30%-40%) in the later stage to avoid flash.Structural adaptation: Increase pressure to 80-100MPa and speed to 60%-80% of rated speed for thin-walled and complex parts; control pressure at 60-80MPa and slow speed to 40%-60% for thick-walled parts, with properly extended filling time.Note: Ensure tight connection between the nozzle and mold gate to prevent melt leakage and pressure loss.

4. Mold & Mold Temperature Control: Optimize Molding Environment

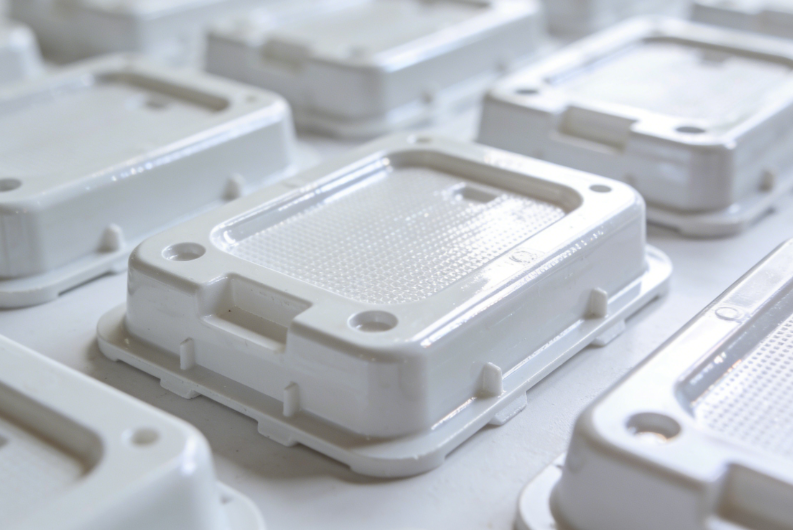

Mold design and temperature control directly affect the surface quality, dimensional stability and demolding effect of ABS parts. The mold must have sufficient rigidity and precision, and the mold temperature must match melt cooling needs to avoid defects from uneven cooling.

(1) Mold Design Requirements

Runner: Adopt circular cross-section, main runner: 4-6mm in diameter, sub-runner: 3-5mm in diameter. Gate: Use pin gates for thin-walled parts and side/fan gates for thick-walled parts; the gate size must ensure smooth filling and avoid stress concentration.

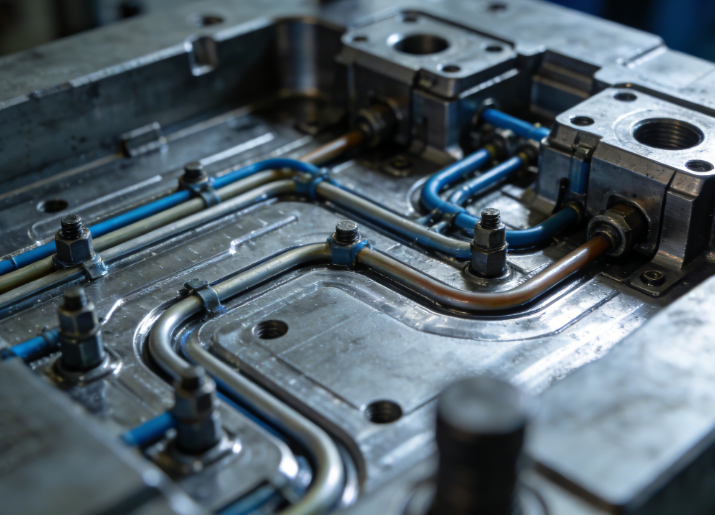

(2) Mold Temperature Control

Basic temperature: 40-80℃. Low temperature causes ripples, shrinkage marks and internal stress, while high temperature prolongs cooling time and increases mold sticking risk. Set temperature at 60-80℃ for high-gloss parts and 40-60℃ for ordinary parts.Cooling channel: Equip the mold with uniform cooling channels (8-10mm in diameter), 15-20mm from the cavity surface, to ensure uniform mold temperature and avoid part warpage.

5. Packing & Cooling: Precise Control to Reduce Shrinkage and Warpage

Packing replenishes melt in the mold cavity to compensate for volume loss from cooling shrinkage, while cooling determines part setting effect. Their parameters must match part wall thickness and mold temperature, which is key to reducing shrinkage cavities and warpage.

(1) Packing Parameters

Packing pressure: 50%-70% of injection pressure. Packing time: 2-4s for 1-3mm wall thickness, 4-6s for 3-6mm, and 6-8s for over 6mm. Excessively long time increases internal stress, while short time leads to insufficient replenishment.

(2) Cooling Parameters

Cooling time: 3-5 times the packing time, with an overall time of 5-15s. The part demolding temperature must be below 60℃ to prevent high-temperature deformation. Extend cooling time and reduce packing pressure for thick-walled parts; shorten cooling time for thin-walled parts to improve efficiency.

6. Demolding & Post-processing: Standardized Operation to Eliminate Internal Stress

ABS parts are prone to deformation and ejection marks due to uneven stress during demolding, and internal stress from molding increases cracking risk. Standardized demolding and targeted post-processing are needed to ensure part quality.

(1) Demolding Requirements

Ejection mechanism: Ensure uniform ejection with sufficient ejector pins of matching diameter to avoid deformation and ejection marks. Draft angle: Control at 1°-2° for parts with buckles, threads and other complex structures to prevent mold sticking or damage during demolding.

(2) Post-processing Specifications

Necessity: High-precision parts need post-processing to eliminate internal stress and avoid cracking in contact with organic solvents or high temperatures. General method: Adopt hot air annealing at 60-80℃ for 1-2h, then cool to room temperature naturally with the oven. The annealing temperature shall not exceed ABS heat distortion temperature to prevent softening.Post-processing can be omitted for small, ordinary parts without special appearance and performance requirements.

7. Common Defects & Quick Solutions

Silver streaks & air bubbles: Undried raw materials or overhigh barrel temperature → Redry materials and lower the rear barrel/nozzle temperature appropriately.

Obvious weld lines: Slow filling speed or low mold temperature → Raise mold temperature, speed up middle filling and set overflow grooves at weld lines.

Shrinkage cavities & dents: Insufficient packing pressure or short cooling time → Increase packing pressure and extend packing/cooling time.

Warpage: Uneven mold temperature or insufficient cooling time → Optimize cooling channels, raise mold temperature and extend cooling time.

Flash: Overhigh injection pressure or large mold clamping clearance → Reduce injection/packing pressure and inspect mold clamping accuracy.

Conclusion

The core of ABS injection molding is precise parameter control and part structure matching. Slight deviations in any link, from raw material drying, temperature/pressure/speed control to mold, packing and cooling matching, may cause part defects. In actual production, adjust parameters targetedly according to part wall thickness, structure and performance requirements based on industry standards. Meanwhile, standardize raw material management, equipment maintenance and mold care. Rational regrind ratio and optimized molding process can reduce production costs and improve efficiency on the premise of ensuring quality. Following the above considerations can effectively reduce molding defects, ensure the consistency and stability of ABS parts, and meet the application needs of various fields.