Plastic Mold Venting System Design and Optimization Strategy

In the field of plastic injection molding, the venting system is often referred to as the "respiratory system" of the mold. It is a critical component that ensures the quality and stability of the final product, yet it is frequently overlooked during the initial design phase. The primary function of a venting system is to expel the air trapped in the mold cavity and the gases generated by the thermal decomposition of the plastic material during the filling phase. If these gases cannot escape efficiently, they can cause a range of defects, including burns, short shots, gas bubbles, and poor weld lines. This article provides a comprehensive overview of the design principles, key parameters, structural types, and optimization strategies for plastic mold venting systems.

1. Core Design Principles and Significance

The design of an effective venting system is governed by four fundamental principles that must be balanced to achieve optimal results.

1.1 Strategic PlacementVents must be positioned precisely at the locations where air is most likely to accumulate. These "dead spots" typically include the furthest points from the gate (the end of fill), sharp corners or deep pockets within the cavity, and the convergence points of multiple melt fronts (weld lines). Placing vents in these areas ensures that the advancing plastic melt pushes the air directly into the exhaust channels.

1.2 Precision SizingThe dimensions of the vent (depth, width, and length) are critical. The core challenge is to create a gap that is large enough to allow rapid gas escape but small enough to prevent the molten plastic from flowing out (known as flashing). The allowable gap varies significantly depending on the viscosity of the plastic material.

1.3 Unobstructed Exhaust PathThe vent channel must provide a clear and direct path to the outside of the mold. Any bends, constrictions, or dead ends in the vent will impede airflow and cause backpressure. Additionally, the vent should be polished smooth to prevent the accumulation of burnt plastic residue.

1.4 Aesthetic ConsiderationsVents should be avoided on critical cosmetic surfaces of the part. If a vent must be placed near an aesthetic area, it should be designed to minimize surface marks, such as using a "stepped" vent design that recesses the exhaust channel away from the part surface.

2. Key Venting Parameters and Material Specifics

The physical dimensions of the vent are determined by the flow properties of the plastic being molded.

2.1 Vent Depth (The Critical Limit)Depth is the most important parameter, as exceeding the material's "flash limit" will ruin the part.

Low Viscosity Materials (PE, PP, LDPE): These materials flow very easily. Vent depth should be strictly controlled between 0.02 mm and 0.05 mm.

Medium Viscosity Materials (ABS, PS, HIPS): These are more forgiving. A depth of 0.015 mm to 0.03 mm is standard.

High Viscosity Materials (PC, PA, PMMA, PBT): These materials have high resistance to flow. Vents can be slightly deeper, typically 0.01 mm to 0.02 mm, to facilitate gas escape without risking flash.

2.2 Vent Width and Length

Width: Determines the volume of gas that can be expelled per unit time. A width of 3 mm to 5 mm is standard for most applications. For large parts or high-flow materials, widths of 10 mm to 15 mm may be necessary to prevent backpressure.

Length: A typical vent length is 5 mm to 10 mm. Beyond this length, the vent can be deepened (stepped) to 0.1 mm to 0.2 mm to further reduce resistance and prevent clogging.

3. Common Venting Structures and Applications

There are several methods to implement venting, each suitable for different mold geometries and part requirements.

3.1 Parting Line VentsThis is the most common and cost-effective method. It utilizes the interface between the fixed and moving halves of the mold. A shallow groove is machined into one side of the parting line, extending from the cavity to the outside of the mold. This method is ideal for flat or simple parts but is limited by the mold's parting line geometry.

3.2 Insert and Ejector Pin VentsFor complex cavities where the parting line is inaccessible, vents can be created using the clearance between moving components.

Inserts: The fit clearance between a cavity insert and the mold plate is set to 0.01 mm to 0.02 mm, allowing gas to seep through and exit via channels in the plate.

Ejector Pins: Axial grooves (1 mm to 2 mm wide) are ground into the sides of ejector pins. As the pin moves, gas is channeled down the grooves into the ejector plate area and expelled.

3.3 Vent Pins and Sintered Metal VentsFor deep, narrow, or hard-to-reach areas, standard vents are ineffective.

Vent Pins: These are specialized pins with a porous structure or precise grooves that allow gas to pass through while blocking plastic.

Sintered Metal Inserts: These are cylindrical inserts made from compressed and sintered metal powder, creating a porous matrix. They offer extremely high exhaust efficiency (3 to 5 times that of conventional vents) and are often used in high-speed, high-precision molding. However, they require regular ultrasonic cleaning to prevent clogging.

3.4 Vacuum VentingIn high-end applications (e.g., optical lenses, medical devices), even micro-bubbles are unacceptable. A vacuum pump is connected to the mold to actively draw air out of the cavity before injection begins. This method eliminates air-related defects entirely but requires complex equipment and precise timing control.

4. Optimization, Maintenance, and Troubleshooting

A well-designed venting system requires proper process adjustment and regular maintenance to remain effective.

4.1 Process Parameter OptimizationIf venting is marginal, adjusting the molding parameters can often compensate:

Injection Speed: A "Slow-Fast-Slow" profile is recommended. Starting slowly allows air to escape before the melt front blocks the vents.

Temperature Control: Increasing the melt and mold temperature reduces viscosity, making it easier for gases to separate from the plastic and escape through the vents.

Back Pressure: Applying a back pressure of 3 to 5 bar helps compress the plastic in the barrel, removing trapped air before it enters the mold.

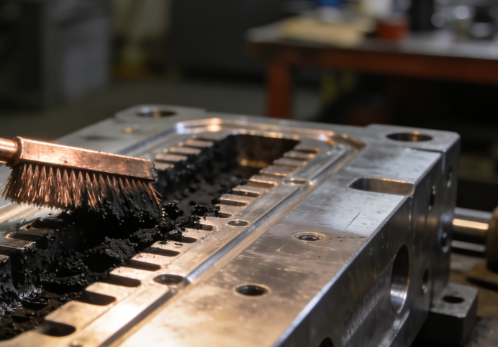

4.2 MaintenanceVents are prone to clogging with carbonized plastic (burns) and debris. It is recommended to clean the vents every 10,000 to 20,000 cycles using fine wire brushes, ultrasonic cleaners, or specialized vent cleaning tools. Neglecting maintenance will gradually reduce exhaust efficiency and lead to defects.

4.3 Defect Analysis

Burn Marks (Black Spots): Indicate adiabatic compression of air. Solution: Increase vent size or add vents at the burn location; reduce injection speed.

Short Shots: Indicate excessive backpressure from trapped air. Solution: Optimize vent placement; increase vent width; check for clogs.

Bubbles and Voids: Indicate dissolved gases or trapped air. Solution: Increase back pressure; improve mold temperature; clean vents.

Weld Lines: Indicate poor fusion due to gas entrapment. Solution: Vent directly at the weld line; increase melt temperature.

5. Conclusion

The design and optimization of plastic mold venting systems is a sophisticated balancing act that requires a deep understanding of material science, fluid dynamics, and mold engineering. By adhering to the principles of strategic placement, precision sizing, and regular maintenance, mold designers and processors can significantly reduce defects, improve part quality, and enhance production efficiency. As molding technology advances, the importance of effective venting will only continue to grow, especially in the production of thin-walled, high-precision, and complex plastic components.