Matching and Debugging Skills for Injection Pressure and Speed in Molding

Injection pressure and speed are core synergistic parameters in injection molding, determining melt filling state, flow path and product quality. Pressure provides driving force for melt flow, while speed controls filling efficiency and shear degree. Their matching debugging follows the principles of speed first then pressure, gradient matching, material-based parameter setting and segmented control, with targeted adjustments for raw material properties, product structure and mold complexity. The key skills are as follows:

1. Core Matching Principles

Set speed first, adjust pressure later: Determine the speed gradient first, then supplement pressure to overcome flow resistance, avoiding high pressure and speed together.

Graded segmentation with smooth transition: Divide filling into 3-5 segments, control the pressure and speed variation between adjacent segments within 20% to reduce air entrapment and weld lines.

Material-adaptive control: Use higher speed and lower pressure for high-flow raw materials (PE, PP, PS); increase basic pressure and reduce speed for low-flow materials (POM, PC); strictly control shear force for shear-sensitive materials (TPE, PVC) to avoid degradation.

Mold-based parameter setting: Increase front-section pressure and reduce speed for molds with small gates, complex cavities or long runners; do the opposite for simple molds to improve efficiency.

Pressure reserve: Reserve 10%-20% of the rated pressure, and use the minimum effective pressure on the premise of complete filling.

2. Segmented Matching Debugging Method

Divide injection into 3 core stages by cavity filling volume, with adaptive pressure and speed matching for each stage:

Stage 1 (Gate filling, 10%-20% of cavity volume)

Goal: Smooth melt entry into the cavity, avoid shear overheating at the gate.Parameter: Speed 10%-30% of rated speed, pressure 30%-40% of rated pressure; increase pressure first if melt cannot pass the gate.

Stage 2 (Main cavity filling, 60%-70% of cavity volume)

Goal: Rapid and stable filling, reduce weld lines and cold spots.Parameter: Speed 40%-70% of rated speed, pressure 50%-70% of rated pressure; adjust according to material fluidity (higher speed for high-flow materials, lower for low-flow ones). Reduce speed first for flash, increase pressure first for short shot.

Stage 3 (Final filling, 10%-20% of cavity volume)

Goal: Slow filling at the cavity end, release shear stress, prepare for pressure holding.Parameter: Speed 10%-30% of rated speed, pressure 40%-60% of rated pressure; slightly increase pressure for insufficient filling, reduce pressure directly for flash.

Key tip: Set segment switching by actual filling volume with no pressure mutation to avoid melt impact.

3. Adaptive Skills for Different Scenarios

Thin-walled products (wall thickness ≤1.5mm)

Core: Medium-high pressure + medium-high speed; speed 20%-30%/70%-85%/20%-30%, pressure 40%-50%/60%-80%/50%-60% for 3 stages.

Thick-walled products (wall thickness ≥3mm)

Core: Medium-low pressure + medium-low speed; reduce shear heat, speed 10%-20%/30%-50%/10%-20%, pressure 30%-40%/50%-60%/40%-50%.

Complex cavity products

Core: Multi-stage gradient matching; low speed + high pressure at resistance points (ribs, buckles), then increase speed and reduce pressure.

Shear-sensitive materials (TPE, PVC, PC/ABS)

Core: Full-stage low speed + adaptive pressure; reduce overall speed by 20%-30%, increase pressure to ensure filling.

High-flow materials (PE, PP, GPPS)

Core: Medium-high speed + low pressure; control pressure strictly, speed 20%-30%/60%-80%/20%-30%, pressure 30%-40%/40%-60%/30%-50%.

4. Troubleshooting for Mismatch Issues

Troubleshoot with the principle of adjusting speed first, pressure second; single parameter adjustment range ≤10%:

Short shot: Increase pressure by 5%-10% first, then slightly raise speed; lower speed and raise pressure at resistance points for complex molds.

Flash: Reduce speed by 10%-20% first, then lower pressure; adjust stage 1 parameters alone for gate flash.

Obvious weld lines: Increase stage 2 speed for rapid melt convergence, supplement pressure and raise material/mold temperature.

Bubbles/silver streaks: Reduce stage 2 speed for smooth gas exhaust, lower pressure and optimize mold exhaust slots.

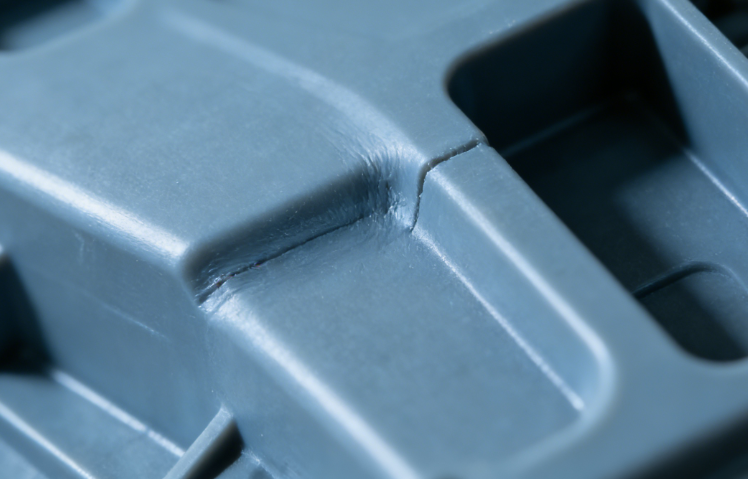

High internal stress/cracking: Reduce full-stage speed by 20%-30%, lower pressure and extend pressure holding switch time.

Gate yellowing/brittleness: Reduce stage 1 speed and pressure, enlarge gate size to reduce shear force.

Cavity end voids/sink marks: Increase stage 3 pressure, slightly raise speed and optimize pressure holding parameters.

5. Standard Debugging Steps

Basic parameter setting: Set material barrel/mold temperature by raw materials, lock mold force with 10%-20% reserve to avoid flash.

Initial speed gradient: Set 3-stage speed as 10%-30%, 40%-70%, 10%-30% of rated speed (slow-medium-slow).

Match basic pressure: Allocate the minimum effective pressure for each stage to ensure smooth melt flow at set speed.

Test and fine-tune: Observe product defects after trial molding, fine-tune by the principle of speed first then pressure, single segment first then adjacent segments.

Record and file: Document pressure, speed, switching position with raw material, product and mold information for future reference.

In summary, the matching of injection pressure and speed is a dynamic optimization process based on melt filling state. Abandon the misunderstanding of "high pressure and speed for all", and realize stable and efficient filling through graded segmentation and material-mold adaptation. Targeted fine-tuning by actual defects can reduce product defect rate, improve production efficiency and consistency, and reduce equipment energy consumption and mold loss.