Repair Methods for Cavity Wear of Injection Molds

Injection mold cavities, the core of plastic molding, are prone to surface scratches, wear depressions and dimensional deviations due to long-term molten material scouring, high-pressure extrusion and demolding friction, which impairs plastic part quality. The core repair principle is graded treatment by wear severity, ensuring repair precision, wear resistance and substrate compatibility, as well as strong bonding between repaired and original areas to prevent secondary peeling. Below are practical graded repair methods, post-repair treatments and anti-wear protection measures for different wear levels.

1. Mild Wear

Mainly occurring at feed inlets and demolding contact areas, with only surface finish affected. Physical polishing is adopted to restore finish without changing the cavity structure, suitable for mirror/textured high-precision cavities.

Mirror cavities: Polish step by step with mold-specific paste (rough grind with green paste + fine grind with white paste) at low speed until the original mirror effect and standard roughness (e.g., Ra0.025μm) are restored, avoiding high-temperature ablation.

Textured cavities: Gently wipe worn areas with non-woven fabric dipped in fine paste to remove scratches only; touch up blurred texture with special repair paste and light polish to retain the original texture.

Ordinary cavities: Lightly grind with 3000+ mesh sandpaper in a single direction, remove grinding marks with 4000 mesh sandpaper, and wipe clean to restore flatness.

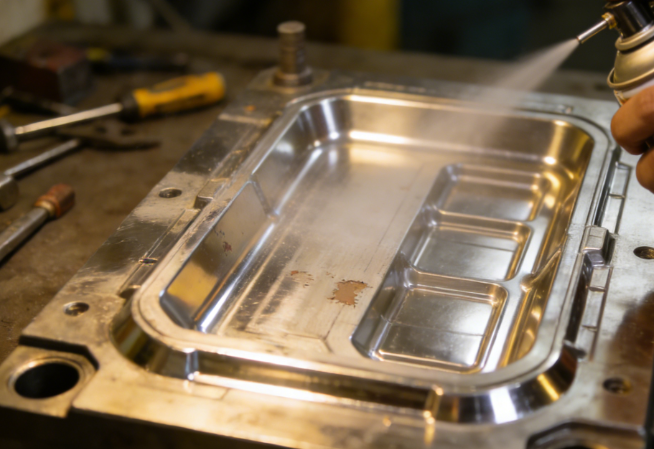

2. Moderate Wear

With local material loss that cannot be fixed by polishing, surface deposition/coating repair is used to form a dense, wear-resistant layer for dimensional compensation, suitable for medium-precision cavities with high repair efficiency.

Cold welding: Surfacing the worn areas with mold steel-matched electrodes to a thickness 0.05-0.1mm higher than the reference surface (no high temperature to avoid deformation/annealing), then grind and polish to restore dimensions and finish.

Hard chrome plating: Apply a 0.05-0.2mm chrome layer on the cavity (hardness ≥HV800) for overall mild wear, compensating dimensions and enhancing wear resistance; fine polish mirror cavities after plating.

Laser cladding: Form a metallurgically bonded cladding layer (hardness ≥HRC55) on worn areas with wear-resistant alloy powder, with better wear resistance than raw mold steel; suitable for hard-to-repair parts like corners and deep grooves, with minor grinding/polishing post-cladding.

3. Severe Wear

Caused by poor maintenance, impurity scouring or excessive molding pressure, with deviated cavity dimensions. Surfacing compensation + precision machining is required to restore the original shape and precision, suitable for heavy-duty/mass production molds.

TIG welding surfacing: Layered surfacing on worn areas with mold steel-matched wires (0.3-0.5mm per layer) to avoid cracking/deformation; preheat the mold as required (e.g., H13 steel to 200-300℃) and cool slowly to reduce welding stress.

CNC precision machining: Take unworn areas as the reference, process the surfaced parts with CNC/EDM equipment to restore the original cavity shape and precision, ensuring overall dimensional deviation ≤0.05mm.

Hardening treatment: Conduct local nitriding/quenching on repaired areas to match the hardness of raw mold steel, then perform final polishing to ensure consistent finish and avoid re-wear.

4. Wear of Special Parts

Special structural parts require targeted repair to avoid damaging surrounding areas and ensure cavity integrity.

Gate bushings: The optimal solution is to replace worn bushings with same-spec ones; if unavailable, laser-clad the inner hole and finish grind to standard aperture for smooth molten material flow.

Corners/deep grooves: Perform local thin-layer surfacing with micro-plasma arc welding (limited operation space), manually grind with small heads and fine polish to meet dimensional and surface precision requirements.

5. Key Post-repair Treatments

Complete the following steps for all repairs to ensure normal mold operation and avoid premature failure of repaired areas:

Accuracy inspection: Test key cavity dimensions and geometric tolerances with calipers, CMM and other tools to ensure compliance with design standards.

Surface cleaning: Remove welding slag, grinding chips and paste residue, wipe with neutral degreaser and blow dry with high-pressure air gun to prevent molten material contamination.

Trial molding: Verify plastic part appearance and dimensional accuracy; fine-tune repairs promptly if issues like material sticking or unsmooth demolding occur.

6. Anti-wear Protection & Prevention

Repair is a remedial measure; adopt the following daily protection to reduce wear from the source and extend cavity service life:

Raw material control: Remove impurities from molten material and install magnetic separators at feed inlets to avoid scouring wear.

Process optimization: Control injection pressure/speed to avoid high-speed scouring; match mold and molten material temperatures to reduce frictional resistance.

Lubrication & release: Spray special release agent on cavities to reduce demolding friction; regularly lubricate ejector pins/guide pillars to avoid uneven stress-induced local wear.

Regular maintenance: Clean cavity residue after each shift; inspect cavities weekly and handle mild wear promptly to prevent aggravation.

Surface hardening: Apply nitriding, titanium plating or PVD coating on new mold cavities to form a protective layer, improving surface hardness and wear resistance.